Reinforce your Structure with Environment Friendly Cold Formed MegaFRAMING

Our Innovative Solutions for MegaFRAMING

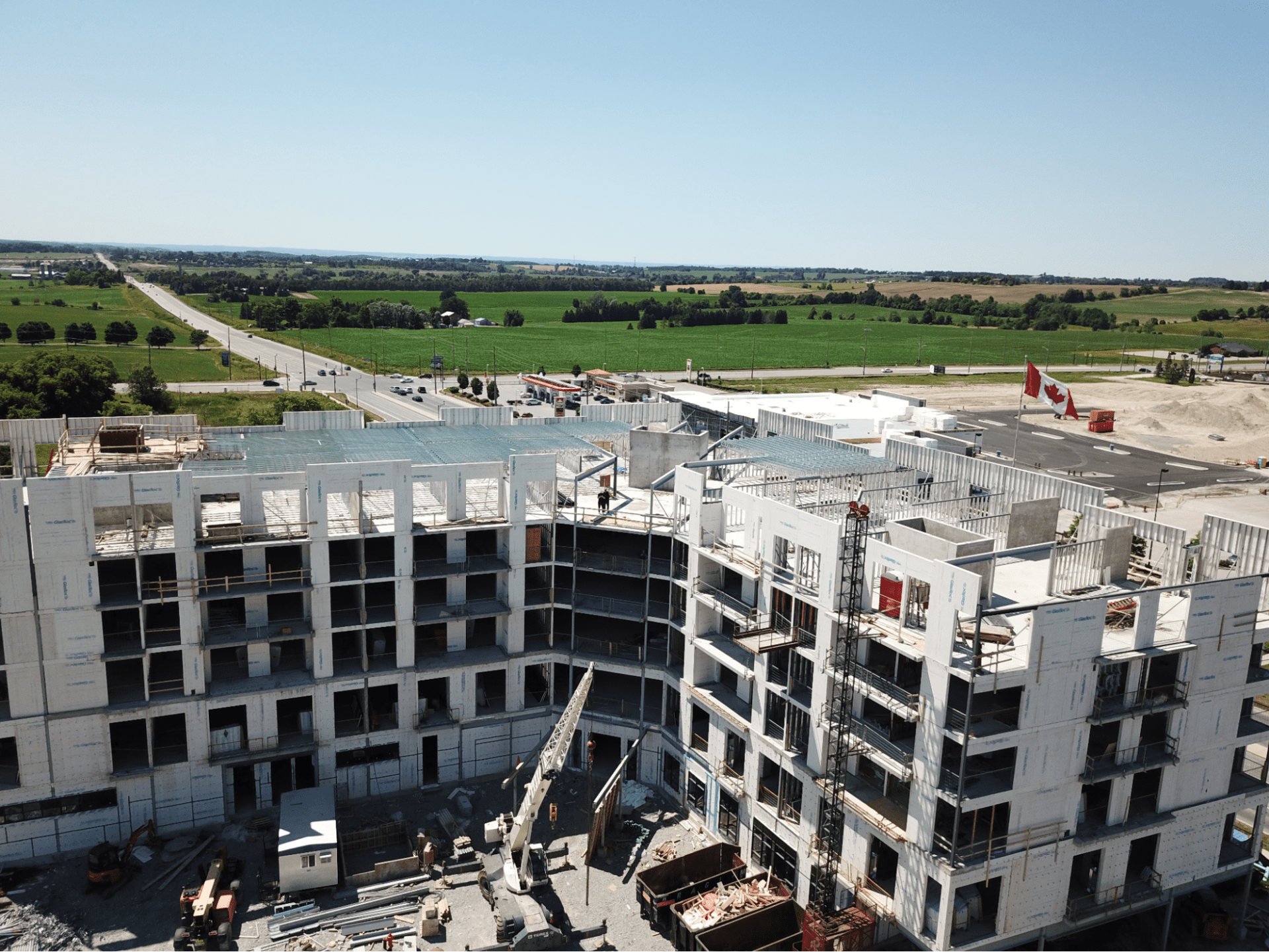

MegaFRAMING is an essential part of any building project. At CPT Group, we provide innovative solutions for steel framing that are designed to reinforce your structure and ensure its stability. Our MegaFRAMING solutions are designed to meet the highest standards of quality and safety and are available in a variety of sizes and materials to suit your needs.

PRODUCTS

STUDS-TRACKS

ACCESSORY

MegaFRAMING Solutions

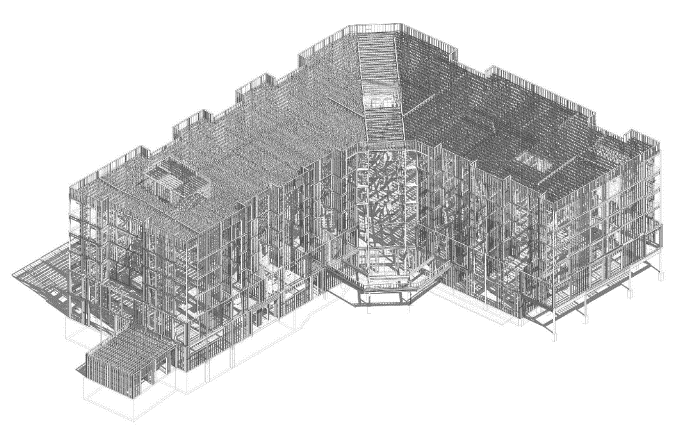

Our cold-formed steel studs, tracks, and joists are used for axial load-bearing walls, curtain walls, floor and ceiling joists, roof rafters, and trusses. Our load-bearing members start at 33 mils (20 gauge) and can be as thick as 97 mils (12 gauge). Lightweight, durable, and galvanized cold-formed steel load-bearing members are available in a selection of sizes, flanges, gauges, and yield strengths to obtain optimal performance for your project.

Customized Solutions

We understand that every project is unique, which is why we offer customized solutions for MegaFRAMING. Our team of experts can work with you to create a customized solution that meets your specific needs and requirements. We can also provide advice and guidance on the best materials and sizes for your project, ensuring that you get the best possible results.

Quality and Safety

At CPT Group, we are committed to providing the highest quality and safety standards for our MegaFRAMING solutions. Our products are designed to meet the highest quality and safety standards and are tested to ensure that they meet all applicable regulations. We also provide ongoing support and maintenance services to ensure your MegaFRAMING solution remains in top condition.

MegaFRAMING Advantages with Canadian Panel Tech

- PERFORMANCE

- COST EFFECTIVE

FIRE RESISTANCE RATING

Steel is a non-combustible material, which is a huge advantage for not being part of the building’s fire load. Many assemblies are available and widely used in Canada and the US. 60 and 120 mins are achievable.

Non-combustibility characteristics of steel have huge commercial and cost advantages as described in cost advantages.

ACCOUSTICAL

Light steel framing offers an effective and efficient method of constructing walls and floors with good acoustic performance. Light Weight Steel Framing (LSF) or Cold Formed Steel (CFS) uses layers of mass with minimal rigid connections in the assemblies to achieve good acoustic performances by applying correct construction practices.

Please refer to our resources pages for some of the suggested LSF-used assemblies in various scenarios of walls & floors and for non-loadbearing and load-bearing applications.

LIGHT CONSTRUCTION

Cold-formed steel has a strength-to-weight ratio of 400 compared to wood 178. Many single- and mid-rise construction projects and buildings can be constructed entirely from CFS without hot-rolled sections.

In addition to the direct cost benefits, there are many indirect cost benefits with reduced footings, transfer slabs, and other lateral resistance structural elements related directly to building weight.

High strength-to-weight ratio

CFS strength-to-weight ratio is significantly higher that of wood or concrete. This feature of being relatively light weight and strong allows CFS to reduce the total weight of the structures which is reflected in direct cost savings in the super structure and indirect cost savings starting from the building foundation.

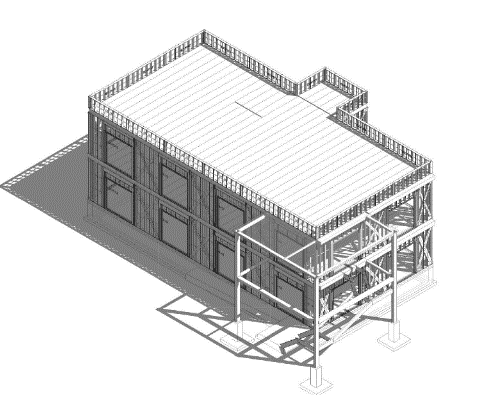

Prefab Construction

Prefab CFS by producing walls and floors panels is extremely popular in load bearing midrise construction. It saves projects schedule and improves quality while building in controlled environment. In addition, most of prefab CFS is utilizing BIM Technology introducing another layer of enhanced collaboration and coordination amongst consultants and construction team.

Lower insurance rates

Building risk insurance premiums are significantly lower with steel vs wood. The savings can easily reach to 70% which is translated in hundreds of thousands to millions depending on project size and cost.

Non-Combustible hidden benefits

Steel framed building doesn’t need detailed fire-safety plans like wood which is high susceptible to fire. Also Steel Framed sites don’t have hidden security related costs that is required with wood construction as per many Canadian jurisdiction.

Product durability

Steel is dimensionally stable and does not expand/ contract with changes in moisture. It wont split, creep or crack with elements exposure unlike other materials.

WALLS

Non-load bearing walls

MegaFRAMING is widely used in interior applications, especially in partitions in high-rise condo buildings, hotels, student dorms, and even in many conventional residential applications.

Load bearing walls

Commercial applications rely almost exclusively on CFS construction in exterior wall applications. Midrise construction using a full CFS solution has become the choice due to the wide range of benefits. Load-bearing walls can be divided mainly into three types:

- Axially loaded walls

- Laterally loaded wind bearing walls

- Shear walls

FLOORS

Floor joists are used in many residential applications, such as in custom homes, commercial magazines, conventional residential, and some midsize construction.

TRUSSES

Steel Trusses are available in many configurations, and they are widely used in full truss systems or mansard roofs in many types of applications. Some of the CFS truss types are:

- Sloped Trusses

- Boxed Trusses

RAFTERS

Sloped roofs with structural CFS members are formed using rafters. A wide range of configurations is possible.

Please check our products page for details on available products.